OBC, or On-Board Charger, is a crucial component in both plug-in hybrid and pure electric vehicles that have a slow-charging interface. The OBC is responsible for converting the alternating current (AC) from the charging pile into the direct current (DC) required for charging the power battery.

With the rapid development of new energy vehicles in recent years, including increases in battery pack capacity and the introduction of 800V voltage platforms, the OBC is facing new demands.

New Demands for OBC

In pure electric vehicles, OBCs traditionally supported power ratings of 3kW and 7kW. This was due to the fact that most AC charging piles used a single-phase 220V input, with the mainstream products on the market having a power rating of 7kW or less. There were also some 380V three-phase AC piles capable of delivering up to 40kW of charging power. Early models from BYD, such as the E5, E6, and electric minibuses, supported 40kW AC charging. However, 40kW AC piles have largely been phased out, and high-power public piles now predominantly use direct current.

Advertisement

On the other hand, the battery capacity of new energy vehicles has been increasing. For instance, plug-in hybrid models used to have battery packs with less than 10kWh capacity, offering an electric range of only a few dozen kilometers. Nowadays, some plug-in hybrids or range-extended models can have battery packs exceeding 50kWh, providing an electric range of over 300 kilometers.

Pure electric vehicles have also evolved from battery packs of around 50kWh a few years ago to over 100kWh, in order to achieve a driving range of more than 700 kilometers.

Thus, using a 7kW AC slow charger on some electric vehicles with large batteries would result in an unacceptably long charging time. In fact, the OBCs in new energy vehicles on the market today generally have power ratings of 6.6kW, 7.2kW, or 3.3kW, which are suitable only for emergency charging or for long-term charging when parked with a home charging pile.

Another aspect is the trend of electric vehicle battery pack voltages moving from 400V to 800V. The 800V battery pack is quickly becoming more common in mid-range models. For the OBC, in addition to converting AC to DC, it also needs to boost the voltage to charge a 400V battery pack. During the boosting process, the power devices and other chips with a 650V rated voltage used in the DC-DC converter cannot be directly applied to an 800V architecture. Therefore, the OBC also needs a new round of upgrades in the era of 800V.

Some automakers have chosen to abandon the OBC altogether, eliminating the AC charging interface and only supporting DC charging. This is considering that in the domestic charging environment, the public DC charging pile penetration is already quite high. According to data from the China Charging Alliance, as of July 2024, the member units of the alliance reported a total of 3.209 million public charging piles, including 1.431 million DC charging piles and 1.778 million AC charging piles.

However, apart from Mainland China and some European countries with high electric vehicle penetration rates, the coverage of DC charging piles in most regions of the world is relatively low, limiting their widespread application. Additionally, the cost of AC piles for home charging is also lower. For example, the price of a 7kW AC home charging pile is nearly 50% cheaper than that of a 7kW DC home charging pile.This is because the essence of a DC charging pile is to move the part of the AC/DC converter from the OBC to the charging pile end, so this additional cost is also transferred to the charging pile. As a result, when users choose a home charging pile, unless it is a model without an AC charging port, they will inevitably choose the AC pile with a lower price.

Therefore, the OBC is still a standard configuration for most models of new energy vehicles. In addition to charging needs, the OBC is also needed for external power output, such as when camping and needing to output to some electrical equipment from the electric vehicle, which requires the OBC to work in reverse, converting the DC power output from the battery into the 220V AC power used by household appliances.

The trend of high power density and high voltage of OBC, the third-generation semiconductor is the first choice.

As mentioned earlier, with the increase of the battery capacity of electric vehicles, the traditional OBC below 7kW can no longer meet the needs. Therefore, some manufacturers are currently developing OBC with a power of 11kW to 22kW for pure electric models with large batteries.

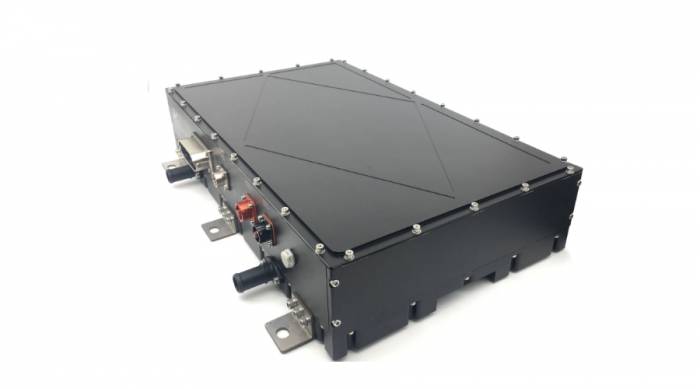

With the increase of power, the volume of the OBC will naturally increase accordingly. However, in the space of the car where every inch is precious, how to improve the power density of the OBC and reduce the volume of the OBC is also one of the key points. In addition, it is necessary to support a power of 11kW to 22kW while also supporting a battery voltage of more than 800V and supporting bidirectional output functions. In practical applications, heat dissipation management, component costs, and electromagnetic compatibility are all issues that high-power OBC needs to face.

Especially under the trend of 800V batteries, the choice of components for the OBC must first be able to operate safely under the voltage conditions of 800V. Secondly, the components need to have higher redundancy to ensure that the operating conditions are below the highest voltage or current of the components, ensuring the reliability of long-term use.

At the IEDM 2023 in December last year, Infineon provided its technical roadmap in the field of OBC: in 2020, the power density of the OBC was about 2kW/L, mainly using silicon-based power semiconductors; by 2024, it will be widely switched to SiC, and the power density will be increased to 4kW/L; after 2025, GaN will be promoted into the OBC, and the power density will be increased to more than 6kW/L.

In Infineon's white paper, it is mentioned that the OBC supporting three-phase AC grid input and 800V battery voltage can use 1200V SiC MOSFET, with a three-phase PFC with CLLC DC/DC resonant converter. SiC MOSFET supports the use of higher switching frequencies, which helps to achieve a more compact and lighter design. Innovative packaging that simplifies heat management helps to improve efficiency and heat dissipation, allowing designers to be more flexible in overall design. Like single-phase designs, three-phase designs can also be used in parallel systems to support higher power output, thereby helping to shorten charging time.

Onsemi also launched a bidirectional OBC solution of 11kW-22kW, which also uses SiC components. Onsemi's OBC solution includes a boost-type three-phase PFC and a bidirectional CLLC full-bridge converter, using the EliteSiC 1200V APM32 power module. This power module is optimized for the 800V battery architecture and is more suitable for high-voltage and power-level OBC. The APM32 series includes a three-phase bridge module for power factor correction (PFC) level, such as the NVXK2VR40WDT2 that integrates temperature sensing with 1200V 40mΩ EliteSiC MOSFET.

Compared with discrete solutions, the APM32 module has a smaller size, better heat dissipation design, lower stray inductance, lower internal bonding resistance, stronger current capacity, better EMC performance, and higher reliability, which helps to design high-performance bidirectional OBC.In addition to SiC, OBC solutions employing GaN devices can achieve higher power density, and currently, several manufacturers are actively developing related products. According to TI's data, using their GaN power devices can achieve CLLLC switching frequencies of over 500kHz and PFC switching frequencies of 120kHz, while integrating gate drivers simplifies system-level design. The power density of OBCs using GaN can be higher than that of OBCs using SiC, and the system conversion efficiency can reach as high as 96.5%.

In conclusion, before charging infrastructure becomes globally widespread, OBCs will continue to be a long-term presence in new energy vehicles, thus remaining a market with tremendous development potential. In this process, OBCs will continue to evolve towards higher power density and support for higher voltage systems.

Comments